Decoration

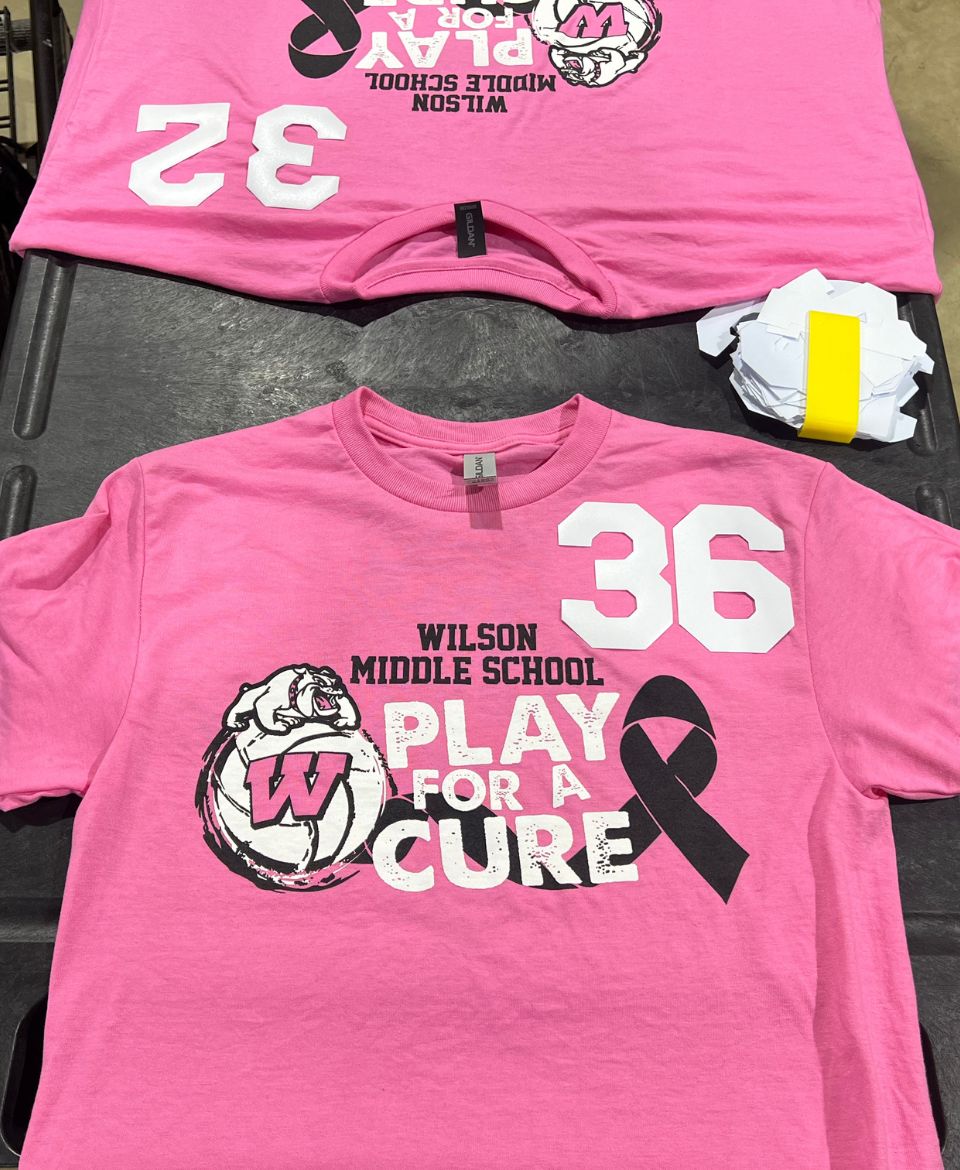

Screen Printing

Screen printing is a versatile printing technique used to apply designs onto various surfaces, most commonly apparel. With this technique a mesh screen is used to transfer ink onto a substrate (like fabric, paper, or plastic). Here is an overview of the process: A stencil (called a screen) is created for each color in the design. The screen is placed on top of the item to be printed. The ink is applied over the screen. A squeegee is used to press the ink through the stencil onto the item. The ink is then forced through the mesh, creating the desired design. The above steps are repeated for each color in the design.

PRos

- Durability: Screen-printed designs tend to be long-lasting and withstand multiple washes.

- Vibrant colors: The technique allows for bold, vivid colors that stand out.

- Cost-effective for large runs: Once set up, it's efficient for printing many items.

- Versatility: Can be used on various materials and surfaces.

- Special effects: Allows for specialty inks like glitter, puff, or glow-in-the-dark.

Cons

- Setup time and cost: Creating screens can be time-consuming and expensive, especially for complex designs.

- Limited detail: Not ideal for photorealistic or highly detailed images.

- Color limitations: Each color requires a separate screen, making multi-color designs more complex and costly.

- Not cost-effective for small runs: The initial setup makes it less economical for printing just a few items.

Best for:

T-shirts, tote bags, posters, signage.

Embroidery

A method where thread is stitched onto fabric to create a raised design. This is done using an embroidery machine that follows a digital design file.

PRos

- Durability: Embroidered designs tend to last longer than printed designs, withstanding multiple washes and wear.

- Texture and dimension: Embroidery adds a tactile, raised element to the design, giving it depth and visual interest.

- Versatility: It can be applied to various materials and items, from clothing to hats, bags, and even shoes.

- Customization: Embroidery allows for highly personalized designs, including names, logos, and intricate patterns.

- Professional appearance: Well-executed embroidery often looks more polished and high-quality than other decoration methods.

- Color options: Embroidery thread comes in a wide range of colors, allowing for vibrant and diverse designs.

Cons

- Cost: Embroidery can be more expensive than other decoration methods, especially for small quantities or complex designs.

- Time-consuming: Hand embroidery is labor-intensive, and even machine embroidery can take longer than methods like screen printing for large batches.

- Limited detail: Very fine details or photorealistic images can be challenging to reproduce accurately in embroidery.

- Material limitations: Some fabrics may not be suitable for embroidery due to their texture or thickness.

- Potential for damage: Improper embroidery can damage delicate fabrics or leave visible holes if removed.

- Setup time: Creating embroidery designs and setting up machines can be time-consuming, especially for new or complex patterns.

Best for:

Apparel, hats, logos, patches.

Sublimation

1. Sublimation: is a decoration method used to transfer designs onto various materials, primarily fabrics and hard surfaces.

2. Partial Sublimation: Is a finished garment decoration. The design is first printed onto special transfer paper using sublimation inks. When heat and pressure are applied, the ink turns into a gas that permeates the fibers or surface of the target material, creating a permanent, full-color image.

PRos

- Durability: The designs become part of the material, resulting in long-lasting prints that don't crack, peel, or fade easily.

- Sublimation allows for vibrant, high-quality, full-color designs with smooth color gradients.

- No texture: The design is embedded in the material, leaving no raised surface or texture.

- Customization: Ideal for creating unique, personalized items in small quantities.

Cons

- Limited materials: Works best on white or light-colored polyester fabric. Not suitable for natural fibers like 100% cotton.

- Color limitations: Difficult to achieve true blacks or vibrant colors on dark backgrounds.

- Size limitations: The size of the design is limited by the heat press and transfer paper dimensions.

- Can see white streaks through the logo if the garment has small folds in the fabric before the logo is heat applied.

3. Full Sublimation: Cut and sew sublimation is a garment decoration method that combines sublimation printing with custom garment construction. Large fabric panels are printed using sublimation. These printed panels are then cut into pattern pieces. The pieces are sewn together to create the final garment.

PRos

- All-over printing: Allows for edge-to-edge designs with no limitations on print area.

- Vibrant colors: Sublimation produces bright, long-lasting colors

- Detailed designs: Can achieve intricate, photorealistic prints

- Smooth feel: The design is embedded in the fabric, not printed on top

- Customization: Enables fully customized garments in terms of both design and fit

- Durability: Sublimated designs don't crack, peel, or fade easily

Cons

- Limited fabric options: Works best with polyester or polyester-blend fabrics.

- Higher cost: More labor-intensive than other methods, resulting in higher prices

- Longer production time: Requires more steps than traditional decoration methods

- Potential for imperfections: Slight misalignments can occur during the sewing process

- Minimum order quantities: Often requires larger orders to be cost-effective

- Color limitations on dark fabrics: Sublimation works best on white or light-colored base fabrics

Best for:

Apparel, mugs, phone cases, promotional items

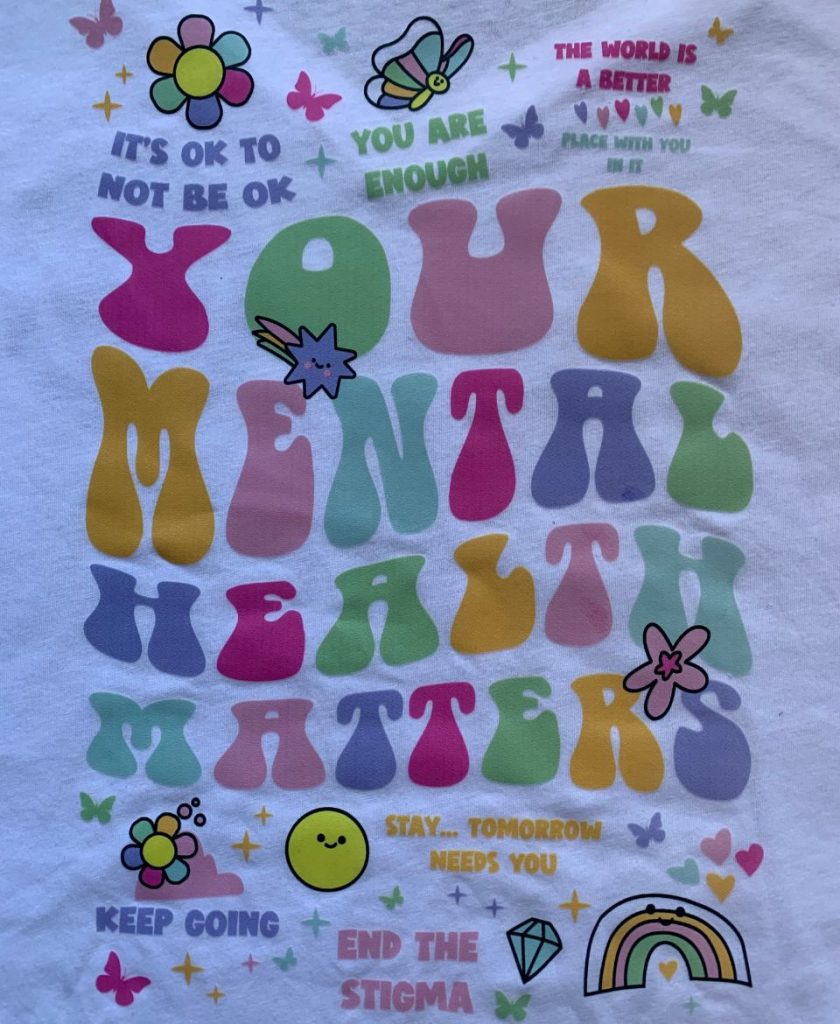

Small Runs

1. Direct-To-Film (DTF): For small quantities of apparel, direct-to-film (DTF) printing is a great option. This digital printing method is where a design is printed onto a special film using a DTF printer. The film is then transferred to apparel using a heat press. DTF works well on cotton, cotton-blend, and polyester fabrics, making it suitable for any apparel.

PRos

- No setup costs, ideal for small runs, high-quality, vibrant colors, full-color designs, can be used on various fabrics, allows for intricate designs, best for on demand printing.

Cons

- Higher cost per unit for large orders, not as durable as screen printing

Best for:

T-shirts, apparel, promotional items.

2. Heat Pressed Vinyl: A vinyl heat press is a machine used to apply heat-transfer vinyl designs onto fabric items like t-shirts, bags, and hats. It uses heat and pressure to bond the vinyl to the fabric. Great for small quantities of apparel.

Works well on cotton, cotton-blend, and polyester fabrics, making it suitable for any apparel. Wonderful to use for name customization on the back of garments.

PRos

- No setup costs, ideal for small runs, high-quality, can be used on various fabrics

Cons

- Not as durable as screen printing, does not allow for intricate designs, limited colors, not suitable for very large production runs, risk of scorching or damaging delicate fabrics, designs may crack or peel over time with heavy use, drying garments on high heat can cause the vinyl to peel.

Best for:

T-shirts, tote bags, mugs, phone cases.

Choosing the Right Method:

The best printing method for you will depend on your specific needs, budget, and desired outcome. Consider factors like:

- Design complexity: Intricate designs are better suited for embroidery or DTF.

- Quantity: Screen printing is cost-effective for large runs, while heat press vinyl and DTF are better for small runs.

- Fabric type: Sublimation and DTF work best on polyester fabrics, while screen printing and embroidery can be used on a wider range of fabrics.

- Budget: Screen printing and embroidery can be more expensive upfront, while heat press vinyl and DTF are more affordable for small runs.

- By carefully considering these factors, you can choose the best printing method to achieve your desired results.